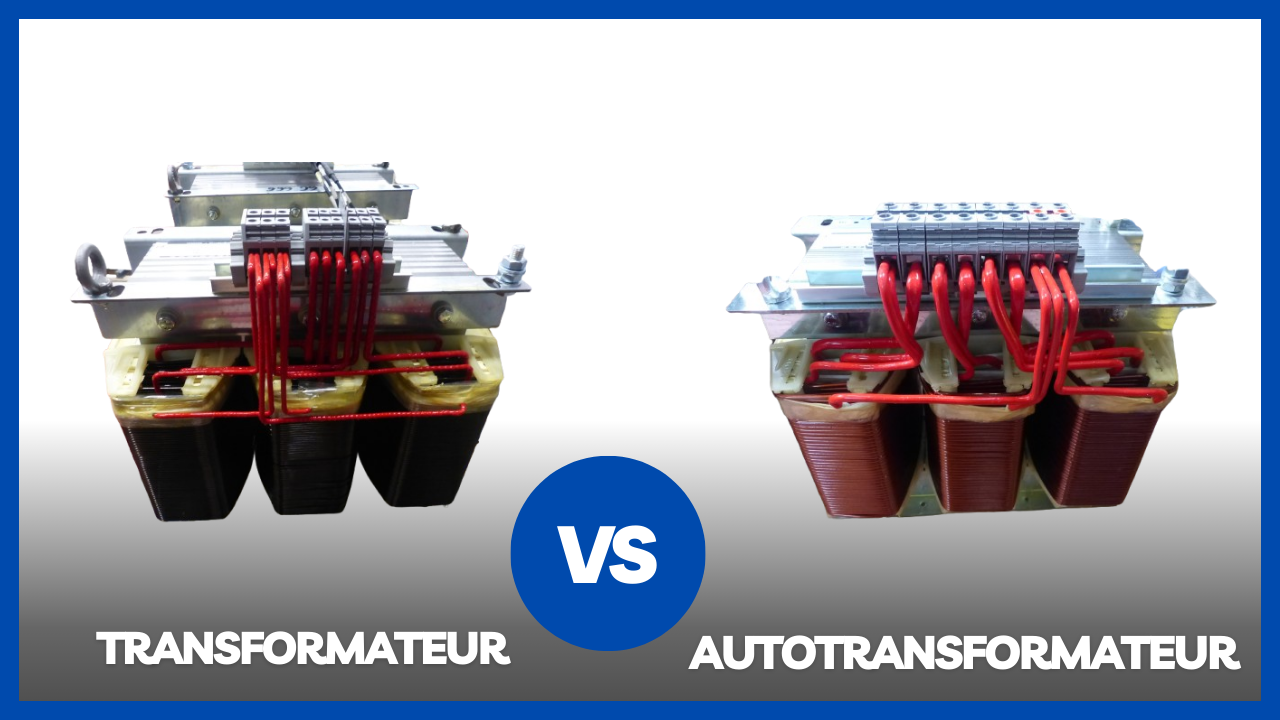

What is the difference between a transformer and an autotransformer?

Transformers and Autotransformers: Understanding the Differences and Applications

Transformers are indispensable pieces of equipment in electrical networks and industrial systems. There are two main categories: conventional transformers and autotransformers. Each has unique characteristics that make them suitable for different uses.

Classic transformers: Versatility and insulation

A conventional transformer consists of two separate windings: the primary and the secondary. These windings are electrically isolated from each other, guaranteeing galvanic isolation between the two circuits. This feature offers a number of advantages, including increased protection thanks to the insulation, which prevents direct current transfer between the circuits, thus protecting the connected equipment. They also allow voltages to be matched between circuits at very different levels.

However, this design implies a higher volume and cost, particularly for high-power applications. This is due to the presence of two completely separate windings, requiring more materials.

Autotransformers: Compact and efficient

Unlike conventional transformers, autotransformers have a single winding, part of which is shared by the primary and secondary circuits. This design offers a number of significant advantages. It reduces costs by using a single winding, which in turn reduces the amount of conductive material required. In addition, autotransformers are more compact and lightweight, making them easier to fit into small spaces. They also offer greater energy efficiency thanks to their optimised design.

However, autotransformers do not provide galvanic isolation between the primary and secondary circuits. This can pose safety problems in certain sensitive applications. They are therefore better suited to low transformer ratios, where this lack of insulation is less critical.

Applications and Choice between the Two Types

The choice between a conventional transformer and an autotransformer depends mainly on the specific needs of the application. Conventional transformers are ideal for applications requiring strict insulation or high transformation ratios. For example, they are commonly used in electrical distribution networks or to supply sensitive electronic equipment. Autotransformers, on the other hand, are widely used in applications with low transformation ratios, such as matching nominal voltages or electrical regulation in three-phase systems.

The Normative Definition of an Autotransformer

According to the International Electrotechnical Commission (IEC), an autotransformer is a transformer with at least two windings in common. This definition highlights the special nature of this type of transformer, which is distinguished by its unique design and specific application.

Focus on the Three-Phase Autotransformer

The three-phase autotransformer follows the same principle. It has just one winding per phase, with the secondary winding forming part of the primary winding. This design is particularly suitable for fine-tuning nominal voltage values in industrial and power systems.

Conclusion

In summary, conventional transformers and autotransformers are complementary tools, each offering specific advantages. The choice of transformer type should be guided by the technical requirements and safety constraints of each project. At Le Cosinus, we specialise in the design and manufacture of tailor-made solutions to meet our customers' most demanding needs.